The world is changing, shaking all industries as it moves through climate, political and economic crises. New regulations as well as cost reduction policies push industries into always more energy savings. Yet, custom heat recovery and thermal optimization equipment remain largely underestimated. Amongst those solutions, some are quite unique like skived fin (SKF) aluminium heat exchangers, offering exceptional performance but very little known. Let’s explore its technical aspects and applications.

Unique technology with unique attributes

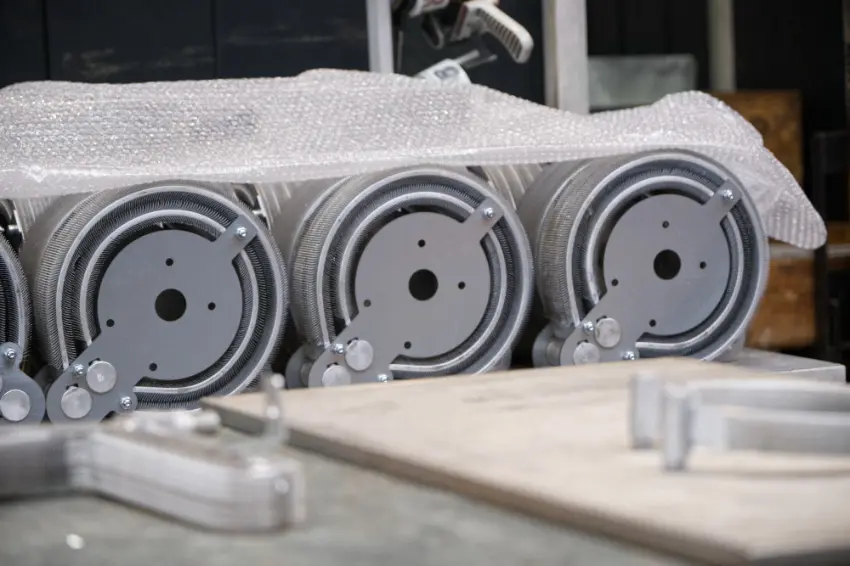

Only designed and made by very few companies in the world, including SAG, skived fin heat exchangers provide top notch performance thanks to the material used as well as their fabrication process.

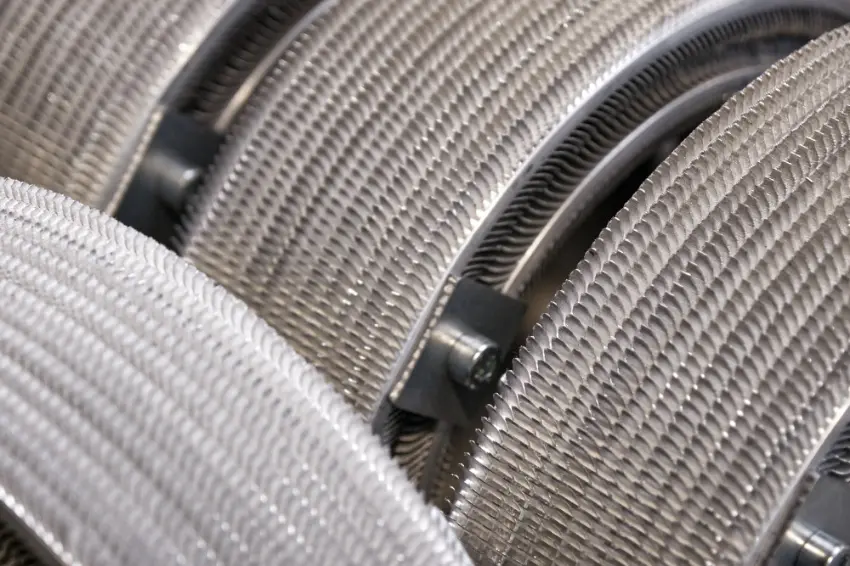

SKF exchangers are made by skiving fins directly into an aluminium frame profile, preventing most material loss as opposed to machining, avoiding any soldering which could decrease the heat transfer coefficient and create fragility areas. This fabrication method offers the following benefits :

The aluminium used also plays a big part in their high efficiency, offering high thermal conductivity as well as the following advantages :

- Lightness

- Malleability (easy to shape by folding or bending) ;

Diverse coatings increase their corrosion resistance, enabling their integration in many applications.

Altogether, these strengths also offer a light, compact product, thanks to its maleability and heat transfer coefficient, which makes it easy to integrate into many machines.

A unique product, yet used across diverse industries

Despite remaining relatively unknown, custom skived fin aluminium heat exchangers are already playing a critical role in multiple industries where heat must be managed under pressure, vibration, and tight space constraints.

In air compressors, particularly oil-free or high-performance units, these exchangers are used to efficiently dissipate heat from the compression process. The skived fin structure allows for a high surface area within a compact volume.

In industrial refrigeration, HVAC or heat pump units, skived fins are used on the high-pressure side, where heat extraction needs to be fast, efficient, and reliable. They optimise the COP (Coefficient of Performance) of the system, which contributes directly to lower energy consumption and better temperature stability under variable loads.

In heavy-duty applications, such as in off-road trucks, the railway industry, construction equipment, and specialized vehicles from manufacturers like MAN, these devices are often integrated into charge air cooling (CAC), oil cooling systems or intercoolers to handle extreme thermal loads, ensuring optimal engine performance and extended service life. The high vibration resistance of these exchangers is also a key advantage for that sector.

Due to the flexibility in design and high precision manufacturing, customized skived fin exchangers meet the exact requirements of various thermal management needs. Whether in stationary industrial units or mobile heavy machinery, they provide a reliable and durable solution for maximizing energy efficiency and minimizing operational risk.

Designed for your unique process

You probably didn’t miss that the word « custom » skived fin exchangers has been used all along this article. It’s because OEM solutions also exist, with their inherent limitations. But custom solutions, like the ones supplied by SAG, offer a tailored design according to your process needs, taking even further the great benefits of this technology.

Whether it’s in industrial equipment, military vehicles, retail and medical refrigeration, or the sectors mentioned before, a custom approach allows for the best results. So, now that you know about it, do you think it’s time to consider SAG’s bespoke skived fin heat exchangers in your process ? You are still unsure about it, but feel like there’s potential ? You need more information ?

Maxime Blondin

Sales & Marketing Officer