Customized Process Equipment includes solutions tailored to specific industrial needs, such as spheres, columns, reactors, filters, and separators. These custom-designed systems are engineered to optimize processes and ensure high performance in a variety of applications, offering flexibility in design, materials, and functionality to meet unique operational requirements.

Spherical process equipment, often used as pressure vessels or storage tanks, is designed to handle high-pressure and high-volume applications in industries such as petrochemicals and liquefied gas storage. The spherical shape provides an inherent structural advantage, distributing stress evenly across the surface, which allows for higher pressure containment with less material compared to cylindrical vessels. These spheres are typically constructed from high-strength carbon steel or stainless steel and can be customized with various nozzles, manways, and internal components to meet specific process requirements. Their compact design maximizes storage capacity while minimizing footprint, making them suitable for both onshore and offshore installations. Spherical vessels are highly durable, easy to maintain, and provide reliable performance under extreme operating conditions, making them an essential component in complex industrial processes.

Air coolers are particularly suitable for environments where water cooling is impractical or unavailable. They provide reliable thermal performance with minimal operational costs, as they rely on ambient air rather than water. API 661 exchangers are built to withstand high pressures and temperatures, often using corrosion-resistant materials for long-term durability. Their modular design allows for easy maintenance and scalability, making them a versatile solution for heat rejection in critical industrial processes.

Columns are vertical process equipment designed for mass transfer operations such as distillation, absorption and stripping. Their tall, cylindrical structure allows for efficient phase separation by providing multiple stages or trays where liquid and gazes interact, enhancing the purity and yield of the desired product.

Customized columns are built to specific process requirements, including diameter, height, internal components (such as trays, packing, and distributors), and materials. They are engineered to withstand high pressures and temperatures, ensuring reliable performance in demanding environments. Their modular design allows for easy maintenance, retrofitting, and scalability, making them essential equipment for continuous and batch processing operations in complex industrial systems.

Industrial reactors are specialized process equipment designed to facilitate chemical reactions under controlled conditions in industries such as chemicals, petrochemicals, pharmaceuticals, and specialty materials production. These vessels are engineered to handle a variety of reaction types, including batch, continuous, catalytic, and high-pressure reactions, ensuring precise control over temperature, pressure, and mixing.

Customized reactors are built with high-grade materials like stainless steel, Hastelloy, or other corrosion-resistant alloys to withstand aggressive chemicals, extreme temperatures, and high pressures. They often include internal components such as agitators, baffles, and heat exchange jackets to optimize reaction efficiency and product quality. Reactors are tailored to specific process needs, offering flexibility, durability, and high performance for complex chemical processes, making them indispensable in modern industrial manufacturing.

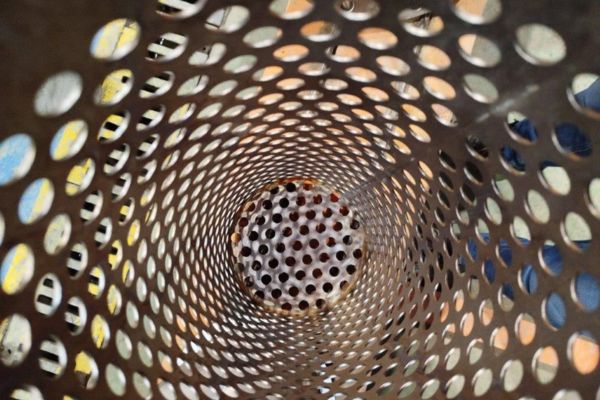

Industrial filters are essential customized process equipment designed to remove impurities, solids, or particulates from liquids and gases in industries such as chemicals, oil and gas, pharmaceuticals, and food processing. These units ensure product purity, protect downstream equipment, and enhance process efficiency by providing reliable filtration solutions tailored to specific operational needs.

Modular and scalable, industrial filters are designed for easy maintenance, cleaning, and replacement, offering long-term reliability and optimal performance.

Industrial separators are critical for phase separation processes like gas-liquid separation, liquidliquid separation, and solid removal, ensuring product quality and protecting downstream equipment.

Customized separators are built to specific operational requirements, with designs including vertical, horizontal, and spherical configurations. Internal components such as demisters, vane packs, and cyclones enhance separation efficiency.

Adding {{itemName}} to cart

Added {{itemName}} to cart