Air Cooled Heat Exchangers (ACHE) use air to efficiently transfer heat, offering compact, energy efficient solutions for industries like oil and gas, power generation, chemical processing, and even renewable energy applications such as nuclear power. With advanced designs like skived fins and API 661, these exchangers provide reliable performance and help reduce operational costs in demanding environments.

Air-cooled heat exchangers designed to API 661 standards are used to dissipate heat from process fluids to ambient air, making them essential in industries such as oil and gas, petrochemicals, power generation, and refineries. These exchangers consist of finned tubes arranged in bundles, with fans forcing or drawing air over the surface to enhance heat transfer. API 661 ensures that these exchangers meet stringent requirements for mechanical design, materials, and performance under harsh operating conditions.

Air coolers are particularly suitable for environments where water cooling is impractical or unavailable. They provide reliable thermal performance with minimal operational costs, as they rely on ambient air rather than water. API 661 exchangers are built to withstand high pressures and temperatures, often using corrosion-resistant materials for long-term durability. Their modular design allows for easy maintenance and scalability, making them a versatile solution for heat rejection in critical industrial processes.

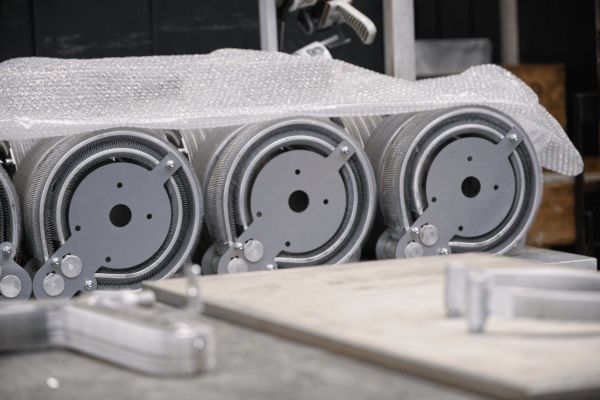

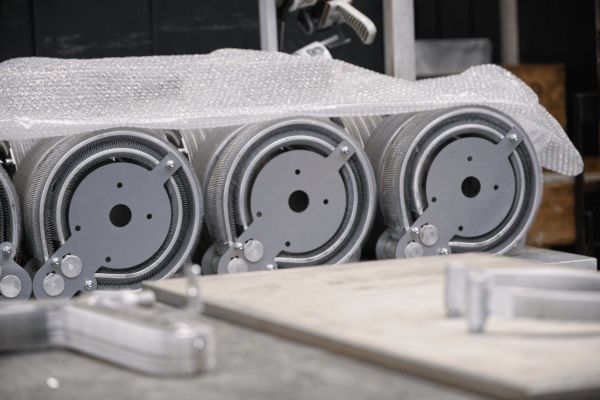

Skived fin heat exchangers consist of a series of aluminum-frame profiles, within which thin fins are cut to increase the heat exchange surface area.

Discover more in our dedicated article here.

Top notch mechanical properties

Excellent pressure resistance (P > 60 bars) thanks to a multi-channel geometric profile ;

Excellent vibration and shock resistance (fins skived from a single piece) ; Lightness.

Integration ease

Flexibility (easy to shape by folding or bending) ;

Compactness (reduced size) thanks to its easy shaping and the optimisation of the transfer coefficients (option of integrating it in housing, panels).

Adding {{itemName}} to cart

Added {{itemName}} to cart