Shell & tube heat exchangers

In modern industry, energy optimization has become a crucial challenge for business competitiveness and sustainability. At the heart of this issue are heat exchangers, the true pillars of industrial energy efficiency. Among the various types of exchangers available, bespoke shell & tube heat exchangers stand out for their versatility and robustness, adapting to a multitude of industrial applications.

What is a tubular heat exchanger ?

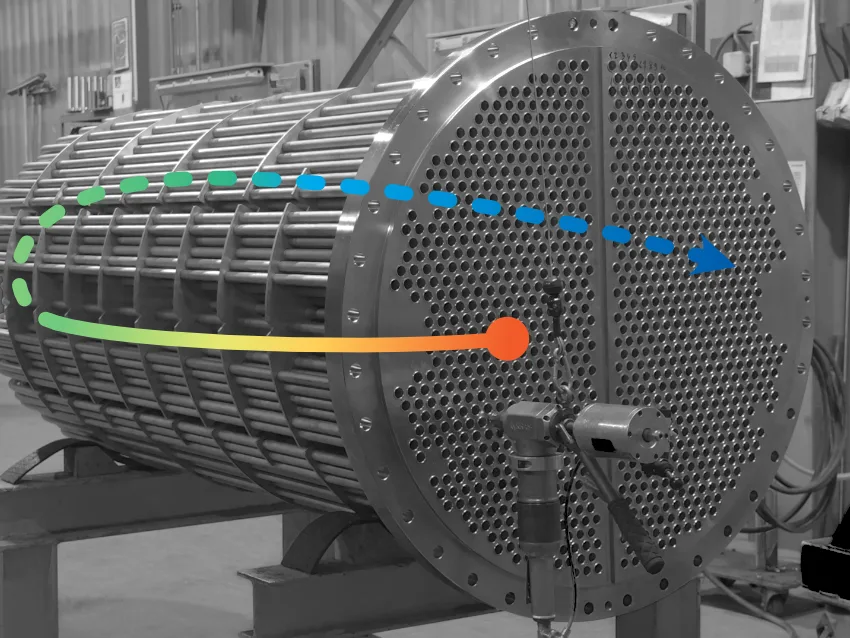

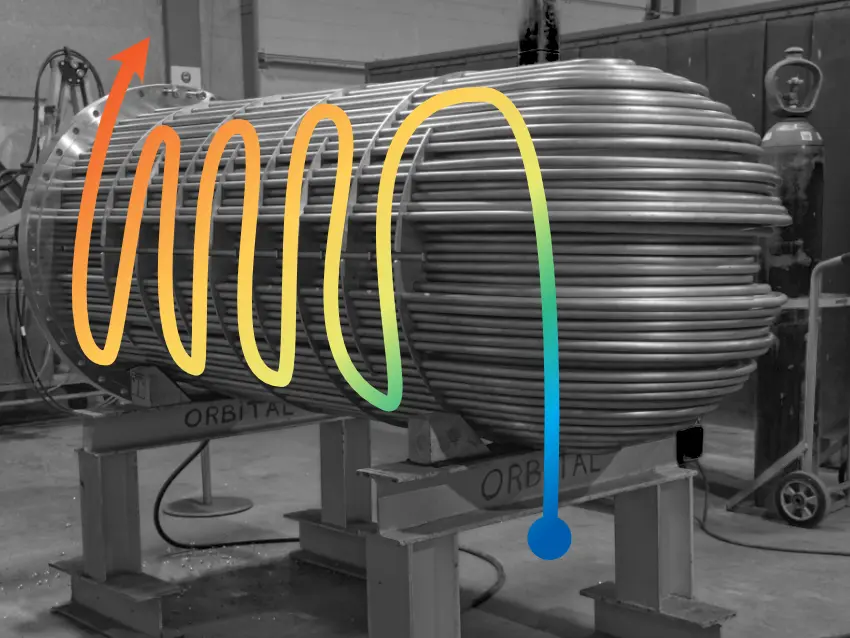

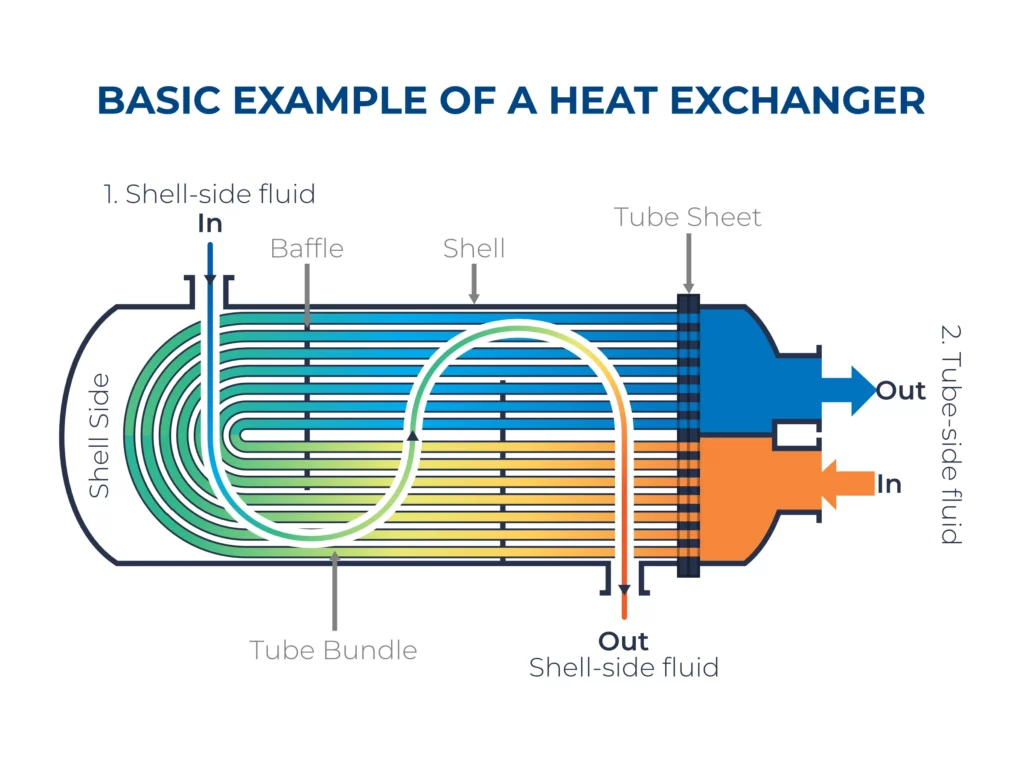

These are thermal devices composed of two main elements : a cylindrical shell (Figure 1) containing a bundle of tubes (Figure 2). This proven design enables thermal exchange between two fluids without mixing them, a fundamental principle in numerous industrial processes.

The customisable design of these exchangers offers remarkable flexibility, allowing adaptation of the exchange surface, tube configuration, and materials used according to the specific needs of each application.

Operating principle and fluids circulation

The operation of a tubular heat exchanger is based on a simple yet efficient principle : two fluids at different temperatures circulate on either side of a metal wall, allowing heat transfer from the hot fluid to the cold fluid.

As illustrated below, the system works with two distinct circuits :

Tube-side circuit : A fluid enters the exchanger tubes via an inlet located on the tube sheet (Figure 3-1) and circulates inside the tubes bundle. After traveling through the tubes, it exits through the outlet on the opposite side. This fluid may be under high pressure or have specific corrosive characteristics.

Shell-side circuit : The second fluid enters into the shell through the inlet (Figure 3-2) and circulates around the tubes. It bathes the entire tube bundle before exiting through the outlet nozzle. Baffles direct the flow to optimize thermal exchange.

Heat exchange optimisation through customisation

Thanks to the use of custom-sized heat exchangers, numerous techniques can be utilized to optimize thermal exchange :

- Use of special tubes (corrugated, welded, machined or skived fins)

- Specific geometry with thermal sizing (baffle placement, nozzles, exchanger shapes according to TEMA standards)

- Material optimization (thickness, alloys, material assemblies by cladding* for the shell, etc.)

- Use of various welding methods (TIG, MAG/MIG, flux, laser, orbital, etc.)

- Use of tubulators, filters, demisters, etc.

- And more.

All these parameters offer wide flexibility to optimize heat transfer capacity, as well as better consideration of your specific needs such as footprint, operating environment, or specific requirements for pressure, corrosion, temperature, maintenance (manholes), and fluid types. Customization also sometimes allows cost reduction by assembling more and less expensive materials, or optimising metals properties by using cladding* to obtain an interior surface with corrosion-resistant alloys and a standard carbon steel exterior surface on a shell.

* Cladding is the bonding of two materials on adjoining surfaces, usually to combine a less corrosion-resistant metal with a more resistant one. This can be done by rolling, explosion bonding, clad plate or weld overlay.

Industrial Applications

Shell & tube heat exchangers find their place in numerous sectors :

And many others, visit our « Sectors »page for more information.

Conclusion

Shell & tube heat exchangers represent a mature and proven technology, but their success lies in their ability to adapt to the specific needs of each industry. Faced with the diversity of applications and the increasing complexity of industrial processes, expertise in designing custom exchangers becomes a major asset.

Whether for energy optimization, solving specific technical problems, or improving performance of existing installations, each project deserves a personalized approach. At SAG, philosophy guides the development of innovative thermal solutions, combining technical expertise with deep understanding of industrial challenges.

Want a quotation for a project ? Contact us via our contact page !

Maxime Blondin

Marketing & Communication Officer